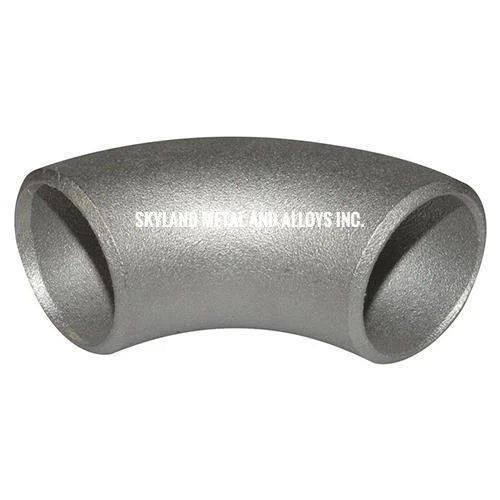

Monel Butt Welded Elbow

Price 200 INR/ Kilograms

MOQ : 10 Kilograms

Monel Butt Welded Elbow Specification

- Coating Type

- None / as requested

- Connection Type

- Butt Weld

- Diameter

- Up to 24 inch

- Sealing Type

- Metal-to-metal

- Bend Radius

- Standard as per ASME/ANSI

- Thread Type

- None (Butt Welded)

- Tolerance

- 0.5 mm

- Temperature Range

- -29C to 538C

- Flexibility

- Rigid

- Yield Strength

- 170 MPa (approx. for Monel 400)

- Tensile Strength

- 480 MPa (approx. for Monel 400)

- Product Type

- Elbow

- Material

- Mild Steel

- Connection

- Butt Welded

- Shape

- Elbow

- Standard

- ASTM B366 / ASME SB366

- Surface Treatment

- Bright Annealed / Polished

- Outer Diameter

- 1/2 inch to 24 inch (12.7mm 609.6mm)

- Section Shape

- Round

- Length

- As per standard specifications / requirement

- Thickness

- Sch 10s, Sch 40s, Sch 80s, custom as required

- Color

- Silver

- Usage

- Industrial piping, oil & gas, chemical processing

- Rated Pressure

- Class 150 to 600

- Application

- Pipeline, connecting pipes at angles

- Material Grade

- Monel 400, Monel K500

- Availability

- Ex-Stock / Custom size on order

- Standards Compliance

- ISO, ANSI, DIN, JIS

- Manufacturing Process

- Seamless / Welded

- Heat Treatment

- Solution Annealed

- Port of Dispatch

- Mumbai

- Magnetism

- Non-Magnetic

- Corrosion Resistance

- Excellent Suitable for marine and chemical environments

- End Type

- Bevelled Ends

- Test Certificates

- EN 10204 3.1 / 3.2

- Angle

- 45, 90, 180

- Packaging Type

- Export-grade box / Wooden case

- Hardness

- Rockwell B75 B90 (for Monel 400)

- Density

- 8.8 g/cm

Monel Butt Welded Elbow Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Monel Butt Welded Elbow

Experience the exclusive paragon of industrial piping-the Monel Butt Welded Elbow, a must-have for demanding marine, chemical, and oil & gas environments. Crafted to brilliant standards including ISO, ANSI, DIN, and JIS, these imposing elbows are available in 45, 90, and 180, with bevelled ends for seamless connections. Buy online to access ex-stock or custom sizes up to 24 inches. With excellent corrosion resistance, non-magnetic properties, and a seamless/welded process, this product blends strength with elegance, delivering enduring reliability and superior performance.

Application Versatility and Surface Suitability

Monel Butt Welded Elbows are ideal for pipeline installations, connecting pipes at precise angles in industrial, chemical, and marine settings. Their exceptional corrosion resistance makes them suitable for harsh environments, while the smooth, polished surface ensures a reliable metal-to-metal seal. With compatibility across various surface treatments and diameters, these elbows comfortably serve oil & gas, chemical processing, and industrial piping sectors. They guarantee robust connections and longevity in demanding operational conditions.

FOB Port, Sample Policy & Certifications

All purchases for Monel Butt Welded Elbows will be securely shipped from the FOB port of Mumbai, ensuring reliable drop-off and transit. Sample policies support hassle-free exchange so customers can confidently verify quality before full procurement. Each product includes robust certifications like EN 10204 3.1/3.2, conforming to ISO, ANSI, and ASTM standards, enhancing your trust in its compliance and authenticity. Export-grade packaging assures the safety of your order during every shipment.

Application Versatility and Surface Suitability

Monel Butt Welded Elbows are ideal for pipeline installations, connecting pipes at precise angles in industrial, chemical, and marine settings. Their exceptional corrosion resistance makes them suitable for harsh environments, while the smooth, polished surface ensures a reliable metal-to-metal seal. With compatibility across various surface treatments and diameters, these elbows comfortably serve oil & gas, chemical processing, and industrial piping sectors. They guarantee robust connections and longevity in demanding operational conditions.

FOB Port, Sample Policy & Certifications

All purchases for Monel Butt Welded Elbows will be securely shipped from the FOB port of Mumbai, ensuring reliable drop-off and transit. Sample policies support hassle-free exchange so customers can confidently verify quality before full procurement. Each product includes robust certifications like EN 10204 3.1/3.2, conforming to ISO, ANSI, and ASTM standards, enhancing your trust in its compliance and authenticity. Export-grade packaging assures the safety of your order during every shipment.

|

Size |

1/2 inch - 24 inch |

|

Material |

Monel |

|

Elbow |

45o / 90o |

|

Elbow Bend Angle |

90o, 45o |

|

Grade |

ASME SB366 Monel 400 |

|

Connection |

Welded, Female, Flange, Male |

|

Thread Size |

BSP/NPT |

|

Brand |

Skyland |

|

Standard |

ASTM B366 UNS N04400 |

FAQ's of Monel Butt Welded Elbow:

Q: How are Monel Butt Welded Elbows typically used in pipeline systems?

A: Monel Butt Welded Elbows are used to connect pipes at specific angles, such as 45, 90, or 180, ensuring smooth flow and direction changes. Their excellent corrosion resistance makes them ideal for industrial, marine, and chemical processing pipelines.Q: What certifications and standards does the Monel Butt Welded Elbow comply with?

A: This product meets international standards like ISO, ANSI, DIN, JIS, ASTM B366, and comes with verified test certificates such as EN 10204 3.1/3.2, ensuring quality and reliability for industrial use.Q: When can I expect shipment and delivery if I place an order?

A: Orders are dispatched from Mumbai, India. Ex-stock items ship promptly, while custom size requests will follow standard manufacturing lead times. Secure shipping and export-grade packaging are ensured for every order.Q: Where can Monel Butt Welded Elbows be applied?

A: These elbows are suitable for use in industrial piping, oil & gas sectors, marine environments, and chemical plants. Their non-magnetic and corrosion-resistant properties make them versatile for diverse, demanding applications.Q: What is the advantage of the seamless manufacturing process for these elbows?

A: The seamless manufacturing process minimizes potential weak points and improves overall structural integrity, ensuring higher pressure and temperature tolerance, especially in environments where reliability is critical.Q: How do I benefit from the product's area of application and material properties?

A: You gain long-lasting durability, resistance to aggressive chemicals, and reliable metal-to-metal sealing with Monel 400/K500 grades, supporting safe operations in high-pressure and high-temperature conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS