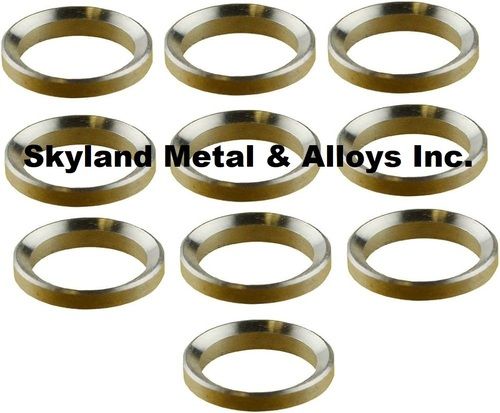

Stainless Steel 384 Washer

Price 15 INR/ Number

Stainless Steel 384 Washer Specification

- Product Form

- Flat Washer

- Recyclable

- Yes

- Heat Resistance

- Yes

- Coating Type

- None (natural stainless steel finish)

- Tensile Strength

- 550 MPa minimum

- Size

- Available in M3 to M30 sizes

- Material Composition %

- Cr 1820%, Ni 810%, Fe balance

- Hardness

- 8095 HRB

- Corrosion Resistant

- Yes, excellent corrosion resistance

- Diameter

- Common sizes from 3mm to 30mm

- Product Name

- Stainless Steel 384 Washer

- Steel Type

- Austenitic Stainless Steel

- Steel Product Type

- Washer

- Grade

- 384

- Thickness

- Typically ranges from 0.5mm to 5mm

- Shape

- Circular

- Steel Standard

- ASTM A240 / ASME SA240

- Surface

- Smooth, clean

- Composition

- Chromium-Nickel Stainless Steel

- Application

- Fastening, securing components in machinery and construction

- Dimension (L*W*H)

- Standard dimensions as per DIN 125 / ISO 7089

- Weight

- Varies depending on size; typically ranges from 0.5g to 8g per piece

- Color

- Silver/Metallic

- Material Grade

- 384 Stainless Steel

- Finish Type

- Bright polished / Matte

- Usage

- Industrial, mechanical, electrical applications

- Edge Type

- Deburred, smooth edge for safety

- RoHS Compliance

- Yes

- Density

- 7.9 g/cm³

- Inner Hole Diameter

- Typically from 3mm to 30mm depending on washer size

- Manufacturing Process

- Cold punched and machined

- ISO Certification

- ISO 9001:2015 Certified manufacturing

- Thermal Expansion Coefficient

- 16.5 µm/m°C

- Custom Sizes

- Available upon request

- Magnetism

- Non-magnetic in annealed condition

- Packing Type

- Packed in poly bags or cartons as per quantity

About Stainless Steel 384 Washer

384 is a stainless steel that has lower work-hardening char- acteristics than Type 305. It is in the 18-8 family of stainless steels and is included in most AN and MS specifications. 316 stainless steel has the highest degree of corrosion resistance of the commonly- used 18-8 stainless steels.Durability and Corrosion Resistance

Made from grade 384 austenitic stainless steel, these washers offer outstanding corrosion resistance and can tolerate harsh environments and high temperatures up to 870C. This makes them highly suitable for both indoor and outdoor use, especially in demanding industrial and construction sectors where longevity and reliability are crucial.

Precision Manufacturing and Safety

Manufactured through cold punching and machining, each washer features a deburred, smooth edge to enhance safety during handling and installation. Their adherence to DIN 125 and ISO 7089 standards ensures dimensional accuracy and a perfect fit, while the surface is kept clean and bright polished for effective performance and an aesthetic finish.

FAQ's of Stainless Steel 384 Washer:

Q: How are Stainless Steel 384 Washers manufactured?

A: These washers are produced using a cold punching and machining process, followed by deburring to ensure smooth, safe edges. This method guarantees uniform dimensions and a high-quality finish.Q: What are the main benefits of using Stainless Steel 384 Washers?

A: The primary benefits include excellent corrosion and heat resistance, high tensile strength, and safety features like deburred edges. They are also RoHS compliant, recyclable, and manufactured in an ISO 9001:2015 certified facility.Q: Where are these washers commonly used?

A: Stainless Steel 384 Washers are typically used in machinery, construction, electrical systems, and other fastening applications that demand reliable, corrosion-resistant components.Q: When should I choose a non-magnetic washer like this?

A: Select a non-magnetic washer-such as the Stainless Steel 384 Washer in its annealed condition-when working in environments where interference with sensitive electronic equipment must be minimized.Q: What is the process for obtaining custom sizes?

A: Custom sizes are available upon request. Simply share the required dimensions and application details with the supplier or manufacturer to receive tailored washers.Q: How can I be sure these washers meet international standards?

A: These washers are manufactured according to ASTM A240/ASME SA240 and DIN 125 / ISO 7089 standards, with ISO 9001:2015 certification ensuring stringent quality management.Q: What advantages does the bright polished or matte finish provide?

A: The choice of a bright polished or matte finish offers both practical and aesthetic benefits-enhancing corrosion resistance, simplifying cleaning, and providing a professional appearance to assemblies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Products Category

Stainless Steel Electropolish Tube

Price 555 INR / Meter

Minimum Order Quantity : 10

Product Name : Steel Products

Steel Type : Stainless Steel

Application : Construction

Color : Silver

Stainless Steel Swage Nipple

Price 10 INR / Unit

Minimum Order Quantity : 10 Units

Product Name : Steel Products

Steel Type : Stainless Steel

Application : Construction

Color : Silver

Stainless Steel Butt Weld Reducer

Price 40 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Product Name : Steel Products

Steel Type : Stainless Steel

Application : Construction

Color : Silver

Stainless Steel 317L Coupling

Price 20 INR / Unit

Minimum Order Quantity : 10 Units

Product Name : Steel Products

Steel Type : Stainless Steel

Application : Construction

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS