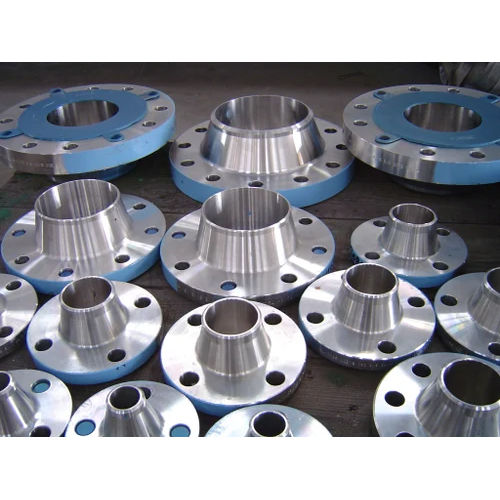

Stainless Steel Inconel Flange

Price 260 INR/ Number

Stainless Steel Inconel Flange Specification

- Grade

- Inconel 600/625/800/825

- Dimension (L*W*H)

- Customizable as per requirement

- Purity

- 99.9% Nickel (Inconel Grade Material)

- Feature

- High strength, Corrosion resistance, Heat resistance, Easy installation

- Application

- Oil & Gas, Chemical Industry, Power Plant, Shipbuilding, Petrochemical, Water System, etc.

- Product Type

- Flange

- Material

- Inconel Stainless Steel (e.g., Inconel 600, Inconel 625, Inconel 800, Inconel 825)

- Standard

- ASTM, ANSI, DIN, JIS, EN, GB

- Shape

- Round

- Surface

- Bright, Sand Blasting, Pickled, Polished

- Connection

- Welded, Threaded, Slip-on, Blind, Socket Weld, Lap Joint, Orifice

- Technics

- Forged, Casting, Machined

- Pressure

- 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

- Size

- 1/2 to 48 (DN15DN1200)

- Color

- Silver/Grey

Stainless Steel Inconel Flange Trade Information

- Minimum Order Quantity

- 50 Number

- Payment Terms

- Cash in Advance (CID), Paypal, Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Per Day

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Stainless Steel Inconel Flange

Owing to the expertise of our professionals, we have emerged as the foremost organization of an excellent quality array of Inconel Flanges. Our offered flanges are highly demanded in the market for their compact design, corrosion-resistance and durability. These flanges are manufactured with the help of fine grade raw-material and progressive technology in adherence to set industry norms at vendors' end. Moreover, flanges offered by us can also be availed in various sizes and shapes as per different requirements of our precious clients.

Features:

- Precisely designed

- Easy to install

- Resistant against corrosion

- Grades: 600, 601, 625, 800, 825 ;

- Size: 1/2 inch - 48 inch (15mm - 1200mm)

- Types: Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint

- Standard: ANSI/ASME B16.5, ANSI B16.47 API, DIN, JIS, BS

Engineered for Extreme Performance

Built with Inconel stainless steel grades (600/625/800/825), our flanges handle pressures up to 2500LB and temperatures up to 1100C. Their robust construction ensures long-term durability and reliability in high-stress environments, making them a trusted choice for critical industrial infrastructure.

Diverse Applications and Customization

These flanges are designed for a wide range of fields including oil & gas, power plants, petrochemicals, and shipbuilding. Available with customized dimensions, packaging, and mechanical properties, they can be tailored precisely to project requirements and installation needs.

Certified Quality and Compliance

Manufactured under ISO 9001:2015-certified processes and compliant with NACE MR0175, these products uphold the strictest quality standards. Their international certification ensures safe operation, consistent performance, and global acceptance across all major industries.

FAQ's of Stainless Steel Inconel Flange:

Q: How are Stainless Steel Inconel Flanges manufactured to ensure quality?

A: Our Inconel flanges are produced using forging, casting, and precision machining under an ISO 9001:2015 certified process. Each product meets ASTM, ANSI, DIN, JIS, EN, and GB standards, ensuring consistent quality, performance, and compliance with global requirements.Q: What applications are most suitable for using Inconel flanges with high heat and corrosion resistance?

A: These flanges are best suited for oil & gas, chemical processing, petrochemical, power plant, and shipbuilding industries where exposure to severe temperatures (up to 1100C) and corrosive environments demand exceptional material resilience.Q: When should a specific flange facing type (RF, FF, RTJ) be selected for installation?

A: Raised Face (RF) is preferred for general high-pressure, high-temperature use. Flat Face (FF) suits low-pressure applications where surface alignment is crucial. Ring Type Joint (RTJ) is ideal for very high-pressure and hazardous environments requiring leak-proof sealing.Q: Where can custom dimensions or surface finishes be specified for these flanges?

A: Custom specifications regarding size, dimension, and surface finish (bright, sand blasting, pickled, polished) can be provided during the ordering process. Our manufacturing supports client-specific requirements to ensure optimal fitting and performance in diverse systems.Q: What are the benefits of using Inconel stainless steel for flange material?

A: Inconel stainless steel flanges offer exceptional corrosion resistance, heat tolerance, and mechanical strength. This translates to greater system longevity, reduced maintenance, and reliable operation in extreme service conditions.Q: How does the packaging process ensure the safe delivery of flanges?

A: Products are securely packed in wooden cases, pallets, or custom packaging as requested, providing protection against physical damage and contamination during transit, particularly for export orders and large quantities.Q: What connection and end types are available for these flanges, and how does this impact installation?

A: These flanges support various connections such as welded, threaded, slip-on, blind, socket weld, lap joint, and orifice, along with end types like beveled and plain. This diversity facilitates simple, secure, and adaptable installation across many industrial piping systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Flanges Category

Stainless Steel A182 WNRF Flange

Price 100 INR / Unit

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Size : Different Size

Application : Industrial

Shape : Round

Blind Flanges

Price 100 INR / Unit

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Size : 1/2" 36",>30 inch,01 inch,2030 inch,1020 inch,510 inch,15 inch

Application : industrial

Shape : Round

SABIC Approved Stainless Steel Flanges

Price 100 INR / Unit

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Size : Different Size

Application : Industrial

Shape : Round

Carbon Steel WNRTJ Flanges

Price 250 INR / Unit

Minimum Order Quantity : 10 Units

Material : Carbon Steel

Size : >30 inch,1020 inch,2030 inch,15 inch,01 inch,510 inch

Application : Industrial

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS