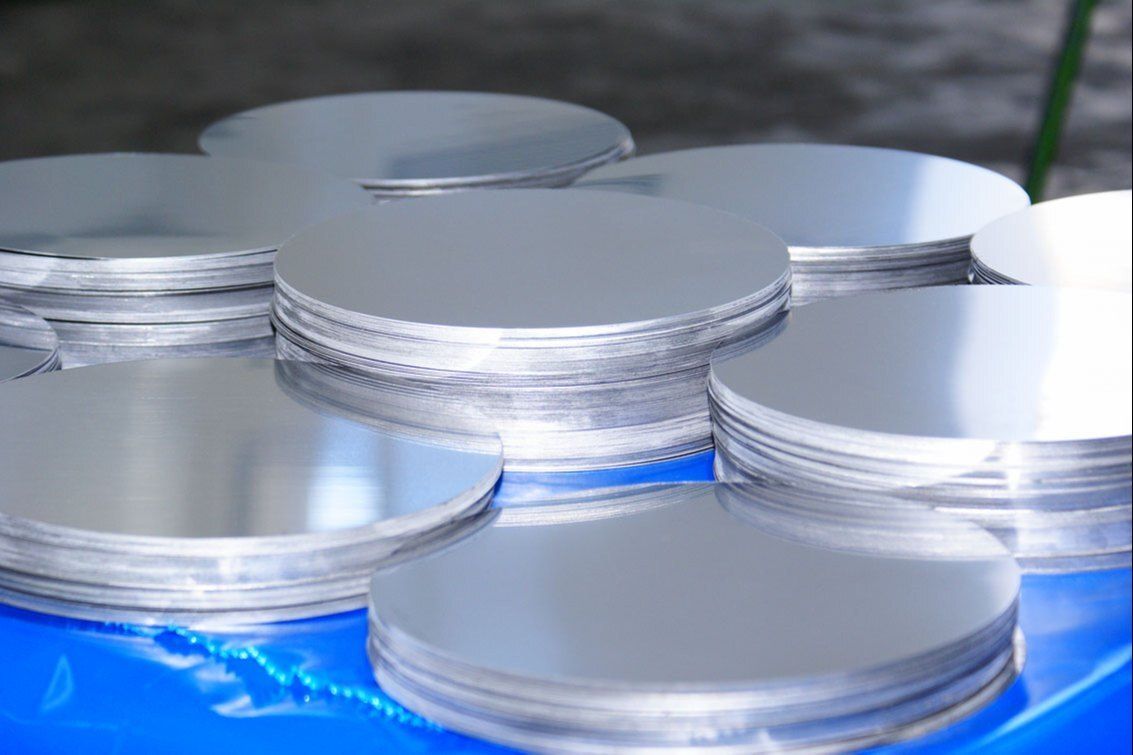

Stainless Steel Triply Circle

Price 190 INR/ Number

Stainless Steel Triply Circle Specification

- Tensile Strength

- 515 MPa (typical for 304 grade)

- Hardness

- HRB 85 (typical)

- Size

- Custom sizes available

- Heat Resistance

- Yes

- Material Composition %

- SS304 (inner, 20-30%), Aluminum (core, 30-40%), SS430 (outer, 30-40%)

- Recyclable

- Yes

- Corrosion Resistant

- Yes

- Product Form

- Triply Layered Disc

- Coating Type

- No external coating

- Diameter

- 100 mm - 400 mm (customizable)

- Product Name

- Stainless Steel Triply Circle

- Steel Type

- Austenitic Stainless Steel

- Steel Product Type

- Metal Circle/Disc/Plate

- Grade

- 304/316/430 (Customizable)

- Thickness

- 0.8 mm - 3.0 mm

- Shape

- Circle

- Steel Standard

- ASTM A240 / AISI / JIS / EN

- Surface

- Bright/Polished/Matte

- Composition

- Stainless steel 304 core, Aluminum layer, Stainless steel 430 base

- Application

- Cookware Manufacturing, Kitchen Utensils, Industrial Use, Food Processing

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- Varies as per size and thickness

- Color

- Silver

- Material Grade

- Triply Stainless Steel

- Finish Type

- Polished/Matte/Customized

- Usage

- Base for cookware (kadai, tawa, saucepans, pressure cookers, etc.)

- Thermal Conductivity

- Enhanced by aluminum core for even heating

- Density

- Approx 7.85 g/cm

- Compatibility

- Suitable for Gas, Induction, and Electric Cooktops

- Food Safe

- Yes, compliant with international food-contact standards

- Manufacturing Technique

- Cold Rolled; Precision Stamped

- Triply Construction

- Inner Food Grade SS304, Core Pure Aluminum, Outer Magnetic SS430

- Edge Design

- Deburred/Rounded/Custom as required

- Surface Treatment

- Oil-Free/Grease-Free

- Lead Free

- Yes

Stainless Steel Triply Circle Trade Information

- Minimum Order Quantity

- 100 Number

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Stainless Steel Triply Circle

Our wide range of products includes Stainless Steel, Carbon Steel and Duplex Steel. Keeping efficiency and quality as the top concern, provides ultimate flexibility in fulfilling each & every customer requirement irrespective of the size of order. The company works with the constructs of quality, affordable prices and innovation and serving the needs of various industries namely Food and Dairy, Heat Exchanger, Shipbuilding, Desalination, Water Treatment and Energy industries, EPC and Pipes for General Engineering Purpose.Engineered for Versatility and Safety

Our Stainless Steel Triply Circles are ideal for cookware bases, offering compatibility with gas, induction, and electric cooktops. The design is fully food-safe, lead-free, and meets international standards, making them suitable for home, commercial, and industrial kitchen applications. Each disc is processed to ensure oil-free, grease-free surfaces for safe food contact.

Superior Material Composition

With an inner SS304 food-grade stainless steel layer, a pure aluminum core, and a magnetic SS430 exterior, these discs optimize both cooking performance and durability. The triply construction guarantees excellent heat distribution and retention, while the magnetic layer enables induction compatibility. Customizable grades (304, 316, 430) and thickness (0.8-3.0 mm) meet specific requirements.

Custom Manufacturing and Finish Options

Every order can be tailored for size, thickness, edge treatment (deburred, rounded, or custom), and surface finish (polished, matte, or as requested). Manufactured using cold-rolled and precision stamping techniques, they ensure high dimensional accuracy and smooth edges, suitable for a range of applications-from household utensils to industrial use.

FAQ's of Stainless Steel Triply Circle:

Q: How is the Stainless Steel Triply Circle manufactured?

A: The circle is produced using a cold-rolled process followed by precision stamping. This method maintains tight tolerances and creates smooth, burr-free edges. The triply construction fuses SS304, pure aluminum, and SS430 layers for optimal strength and performance.Q: What applications are these triply circles suitable for?

A: They are primarily used as base components for cookware such as kadais, tawas, saucepans, and pressure cookers. They are also ideal for kitchen utensils, industrial food processing, and any application where reliable thermal conductivity and food safety are crucial.Q: When should I choose a triply circle with a custom edge?

A: Custom edges are recommended when specific cookware designs demand enhanced safety, aesthetics, or a particular fit. Deburred or rounded edges ensure smoothness, reducing injury risk and providing a neat finish for visible cookware bases.Q: Where can these discs be used in terms of cooking surfaces?

A: These circles are compatible with induction, gas, and electric cooktops due to the magnetic SS430 outer layer and the optimized construction. This makes them highly versatile for different types of kitchens and cooking environments.Q: What are the benefits of the triply construction for cookware?

A: Triply construction combines the corrosion resistance and food safety of SS304, the superior heat conductivity of aluminum, and the magnetic properties of SS430. This results in even heating, energy efficiency, and compatibility with induction cooktops, offering significant advantages over single-material designs.Q: How do I determine the right size and thickness?

A: Sizes and thicknesses are fully customizable depending on your application. Diameter ranges from 100 mm to 400 mm, and thickness from 0.8 mm to 3.0 mm. Simply specify your requirements, and the disc will be manufactured accordingly.Q: What surface treatments and finishes are available?

A: Surfaces can be oil-free or grease-free as standard, with finish options including bright, polished, matte, or custom according to application needs. This helps ensure food-safe contact and matches the desired aesthetic for various products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Products Category

Stainless Steel Cross Union

Price 25 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Silver

Application : Other, Industrial piping, plumbing connections, chemical and food processing pipelines

Steel Type : Stainless Steel

Product Name : Other, Stainless Steel Cross Union

Stainless Steel 304 Washers

Price 12 INR / Number

Minimum Order Quantity : 100

Color : Grey silver chrome

Application : Other, Used for fastening and load distribution in various industrial, mechanical, and construction applications

Steel Type : Other, Austenitic Stainless Steel

Product Name : Other, Stainless Steel 304 Washers

Stainless Steel Circles

Price 190 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Color : Silver

Application : Construction

Steel Type : Stainless Steel

Product Name : Steel Products

Stainless Steel Round Pipe

Price 250 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Color : Silver

Application : Oil Pipe, Gas Pipe

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS