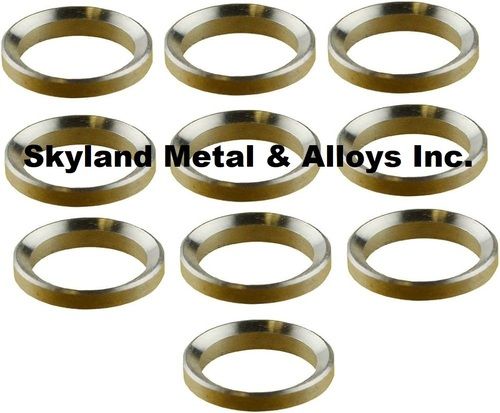

Stainless Steel 202 Washer

Stainless Steel 202 Washer Specification

- Material Composition %

- Cr 17-19%, Ni 4-6%, Mn 7.5-10%, C 0.15%

- Tensile Strength

- 515 MPa (Minimum)

- Heat Resistance

- Yes

- Coating Type

- Uncoated / Natural

- Product Form

- Flat Washer

- Corrosion Resistant

- Yes

- Recyclable

- Yes

- Hardness

- Rockwell B 95 max

- Diameter

- Custom (commonly 5 mm to 100 mm)

- Size

- Standard M3 to M100 or as specified

- Product Name

- Stainless Steel 202 Washer

- Steel Type

- Stainless Steel

- Steel Product Type

- Washer

- Grade

- 202

- Thickness

- 1 mm to 5 mm (customizable)

- Shape

- Round

- Steel Standard

- ASTM A240 / AISI 202

- Surface

- Bright / Polished Finish

- Composition

- Nickel, Chromium, Manganese, Iron

- Application

- Fastening, Securing, Spacing in Industrial, Construction, and Automotive uses

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- Varies as per size and thickness

- Color

- Silver / Metallic

- Material Grade

- SS 202

- Finish Type

- Polished

- Usage

- Machine assembly, piping, automotive, and structural applications

- Magnetic Properties

- Slightly magnetic

- Minimum Order Quantity

- As per supplier policy

- Machinability

- Good

- Storage Conditions

- Store in a dry, dust-free area

- Density

- 7.8 g/cm³

- Packing Type

- Plastic bags, cartons, or as specified

- Melting Point

- 1400°C

- Lead Time

- Ready stock or 1-2 weeks depending on quantity

- Edge Type

- Smooth

Stainless Steel 202 Washer Trade Information

- Minimum Order Quantity

- 100 Number

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Stainless Steel 202 Washer

It isresistant to corrosion, handles extreme temperatures well, and remains environmentally neutral. So, its a great option for several kinds of applications. Learn more about the advantage of stainless steel washers below.Versatile Applications Across Industries

Engineered for reliable fastening, spacing, and securing, the Stainless Steel 202 Washer serves essential roles in machine assembly, piping, automotive, and structural projects. Its adaptability to varied dimensions (M3 to M100 or customized) ensures seamless integration into a multitude of industrial and construction setups, supporting both standard and bespoke requirements.

Superior Material and Durability

Manufactured from high-grade SS 202 stainless steel, these washers offer a minimum tensile strength of 515 MPa and a maximum Rockwell B hardness of 95, ensuring long-lasting performance. The composition of chromium, nickel, manganese, and iron provides substantial corrosion resistance and moderate heat endurance, making them a reliable choice for demanding environments.

Custom Manufacturing and Fast Delivery

Washers are available from ready stock for prompt dispatch or manufactured to custom specifications with a typical lead time of 12 weeks, depending on the quantity. Packaging options include plastic bags and cartons to suit logistics and storage requirements. Suppliers offer tailored dimensions, thickness (1 mm to 5 mm), and finishes, ensuring every order matches precise project needs.

FAQs of Stainless Steel 202 Washer:

Q: How can the Stainless Steel 202 Washer be customized for specific applications?

A: The washers dimensions, thickness (from 1 mm to 5 mm), diameter (5 mm to 100 mm or custom), and surface finish can be tailored as per project requirements. Custom orders are processed based on specifications provided by the customer.Q: What makes the SS 202 Washer suitable for use in industrial and automotive sectors?

A: Its corrosion resistance, moderate heat tolerance, and good machinability make it ideal for fastening, securing, and spacing components in industrial machinery, construction frameworks, and automotive assemblies.Q: When is the Stainless Steel 202 Washer typically delivered after ordering?

A: Ready stock items can be dispatched immediately, whereas customized orders generally require a lead time of 12 weeks, depending on the specified quantity and manufacturing complexity.Q: Where should the SS 202 Washer be stored to maintain its quality?

A: To prevent surface degradation and maintain its mechanical properties, washers should be stored in a dry, dust-free environment, away from moisture and contaminants.Q: How does the manufacturing process ensure quality and compliance?

A: The washers are produced following ASTM A240 / AISI 202 standards using precision machining and surface polishing, with rigorous checks for material composition, tensile strength, and finish to deliver reliable performance.Q: What is the benefit of using SS 202 grade for washers compared to other materials?

A: SS 202 grade offers a balanced profile of corrosion resistance, mechanical strength, and cost efficiency, making it a competitive choice for both heavy-duty and general fastening in industrial, construction, and automotive contexts.Q: What packing options are available for Stainless Steel 202 Washers?

A: Washers are packed in plastic bags and cartons or according to specific customer instructions, ensuring protection during transit and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Products Category

Stainless Steel 384 Washer

Price 15 INR / Number

Minimum Order Quantity : 100 Units

Application : Other, Fastening, securing components in machinery and construction

Product Name : Other, Stainless Steel 384 Washer

Color : Silver/Metallic

Steel Type : Other, Austenitic Stainless Steel

Stainless Steel Forged Flanges

Price 40 INR / Unit

Minimum Order Quantity : 10 Units

Application : Construction

Product Name : Steel Products

Color : Silver

Steel Type : Stainless Steel

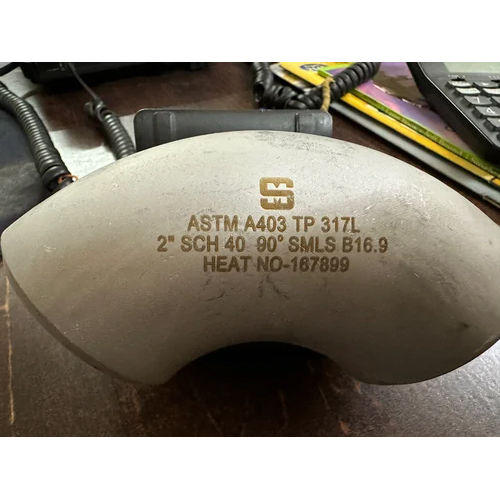

Stainless Steel A182 F317L Elbow

Price 50 INR / Unit

Minimum Order Quantity : 10 Units

Application : Construction

Product Name : Steel Products

Color : Silver

Steel Type : Stainless Steel

Stainless Steel 316-316L Pipes

Price 250 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Application : Construction

Product Name : Steel Products

Color : Silver

Steel Type : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free